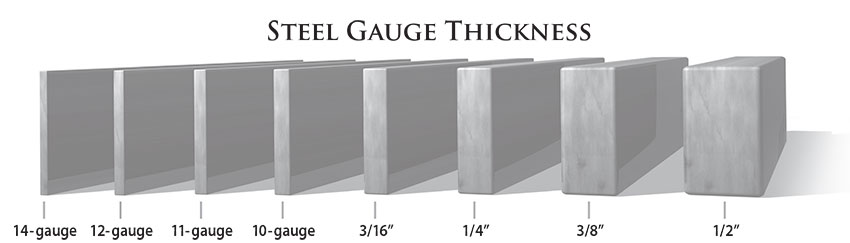

Not all safes are created equal. Door and wall steel thickness determines a safe’s ability to protect. The more steel, the greater protection. Please review the following graph.

The graph illustrates a general rule of steel strength. The bending strength of steel increases by approximately the square of its thickness.

-

12-gauge (.106) steel is 2.86 times stronger than 14-gauge (.075), even though it is only .031 thicker.

-

A safe constructed of 3/16” (.188) steel is about 5.6 times stronger than one constructed from 12-gauge (.106) steel.

-

A safe door made from 1/4” steel is 13.12 times stronger than one made from 12-gauge.

Thicker steel makes a huge difference in the protective ability of a safe. Steel is heavy and expensive but it is also the foundation of any quality safe.

STEEL — A Safe’s First Line of Defense

A safe’s first line of defense is its door and wall construction. The amount of steel in a safe’s door and five walls determines its strength. The more steel used, the greater its protective ability.

The benefit of extra steel thickness is sometimes not fully understood or appreciated. A general rule of steel strength is that it increases by the square of its thickness. If you double the thickness of a piece of steel, it is not merely twice as strong but surprisingly approximately eight times as strong.

A safe door made from 1/4″ (.250) steel is over nine times stronger than one made from 11-gauge (.120) steel. A door made from 10-gauge (.135) steel is over twice as strong as one made from 12-gauge (.106) steel even though it is only .029 thicker (see Steel Strength Chart). Thicker steel can make a huge difference in the protective ability of a safe.

When considering a safe, look at the amount of steel used in its construction. How thick is the steel used in its body? Does it have a steel reinforced door casement? A quality safe will have a steel reinforcement around the door opening.

Door construction is especially critical since it is usually the first point of attack. Is the door formed from thin metal bent to look thick? How thick is the outer door steel? Does the door contain a full second piece of inner door steel?

Most of Champion’s competitors utilize doors constructed from one layer of thin metal (12-gauge or less) formed to look thick. Door edge thicknesses of one to two inches are common. These steel deficient hollow doors are sometimes filled with sheetrock or partial pieces of inner door steel. Many of these doors are visibly impressive but lack the steel to provide foundational rigidity. Don’t be fooled by thick appearing hollow doors even if they carry impressive national brands. Placing a famous brand on a steel deficient safe does not improve its security.

When it comes to providing security, there is no substitute for steel. The more steel used, the greater the security.